ROBOTransfer - Innovative automatic doffing system for textile machines

We have developed the innovative automatic system ROBOTransfer for doffing winding, twisting, cabling and spinning machines. Bobbins automatic removal from production lines - Yarn bobbins palletization - Pin trolleys or movable creels loading >> Watch the ROBOTransfer system working on production lines

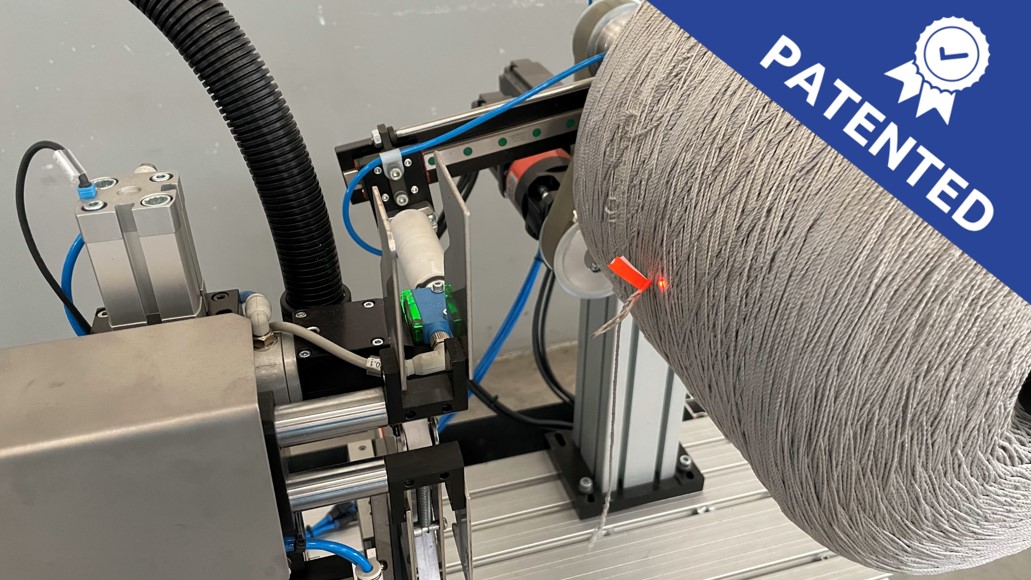

YARNStopper - New device for fixing yarn tails automatically

Properly integrated with robotic cells for bobbins manipulation, YARNStopper is able to search, prepare and fix yarn tails along textile production processes (winding, spinning, cabling, twisting or extrusion). Thanks to the YARNStopper device, is possible to optimize processes costs and automate repetitive activities. There are no operators involved in the knotting process and the device is adaptable to multiple doffing solutions. >> Watch the preview of YARNStopper device

CREELoader - New robotized solution with automatic movable trolleys for loading creels

We have developed the new CREELoader system to feed tufting and warping machines. Thanks to mobiles creels, loaded by modular stationary robots and transported by autonomous and flexible vehicles easily to be implemented (AMR) we are able to load creels automatically. Production departments increase the productivity, by reducing management cost. The system helps to automate heavy and repetitive activities, difficult to be manually managed. The general efficiency of the whole department is optimized, opening the possibility to introduce a MES system for monitoring and scheduling production flows. Thanks to the CREELoader systems it is possible to improve safety of production departments, as well as eliminate completely construction site activities and make these systems easily reconfigurable, completely releasing them from the ground arrangement of the machines and relative production creels It is possible to plan and track, shift by shift, each creeling session by means of the PRIMON AUTOMAZIONI Supervision System, properly customized for specific requirements and MES compatible and linkable >> Watch the preview of CREELoader system for warping departments >> Watch the preview of CREELoader system for tufting departmentsPrimon Automazioni realizza con Festo una linea in grado di produrre un pezzo ogni 2,5 secondi

Tanti integratori di sistemi si stanno interrogando sull’utilizzo o meno degli assi elettrici al posto degli attuatori pneumatici tradizionali. Strategia che Primon Automazioni ha avviato da diverso tempo ottenendo risultati importanti per quanto riguarda affidabilità, flessibilità e modularità. Quella che raccontiamo in queste righe è la storia di una delle tantissime realtà italiane, dove ingegno, spirito imprenditoriale e anche un pizzico di incoscienza hanno dato vita a un’eccellenza a livello internazionale. Primon Automazioni, con sede a Verbania, nasce negli anni ’70 dall’idea imprenditoriale di Vittorino Primon. Fin da subito si specializza nella progettazione e costruzione di quadristica elettrica per aziende di macchine industriali del territorio e oggi vanta l’invidiabile cifra di 1200 sistemi installati in tutto il mondo: macchine automatiche di assemblaggio che rispettano gli standard di sicurezza europei oltre a essere conformi alle indicazioni del piano Industria 4.0. LINK

Primon Automazioni sponsors of Cobianchi high school (Verbania - 2019)

I ragazzi dell’istituto verbanese si sono guadagnati l’accesso al mondiale grazie al secondo posto conquistato, nella categoria Soccer Open, alla RomeCup, torneo nazionale di robotica. Protagonista dell’impresa il team formato da Mahdy Auragh, Lorenzo Ronzani e Tommaso Rovescalli, studenti del triennio che seguono i corsi di informatica, elettronica e telecomunicazioni. Per noi è sempre un piacere aiutare i ragazzi meritevoli e che si sono distinti per le loro capacità ed abilità, per questo abbiamo deciso di supportare economicamente gli studenti in questa fantastica avventura dall'altra parte del mondo ai mondiali di Robotica a Sidney, Australia. Questa esperienza gli aiuterà a crescere e migliorarsi tecnicamente, ma anche ad entrare in contatto con culture diverse e diventare sempre più "cittadini del mondo". Articolo completo LINK

ISH 2019 - THANK YOU AT ALL

Thank you at all from Fulvio, Alessio, Andrea, Michele, Paolo e Gabriella.World Economic Forum: entro il 2025 i robot svolgeranno metà dei nostri lavori attuali

Entro sette anni i robot svolgeranno più di metà dei lavori attualmente esistenti, eppure nessuno dovrà rimanere disoccupato. A rassicurare il mercato sono le proiezioni raccolte in uno studio del World Economic Forum, il quale prevede in cinque anni la creazione di 133 milioni di nuove posizioni lavorative, a fronte dell’automazione di 75 milioni di mansioni. Un conto netto di 58 milioni di nuovi posti, più specializzati, a patto però che gli Stati investano nella formazione dei lavoratori. È già stata ribattezzata «quarta rivoluzione industriale» e negli ultimi anni è stata causa di apprensione tra chi teme di vedere il proprio lavoro sostituito da una macchina >> Continua a leggere il report completo.

Analysis of the technological needs of the ASSEMBLY MACHINERY SECTOR

In preparation for SPS IPC Drives Italia, at the Kilometro Rosso in Bergamo, it has been presented the analysis of the technological needs of the assembly machines sector. The location chosen, not by chance, is at the center of the major industrial companies in Italy. The market calls for a constant personalization of the systems and the technology present in them, and consequently flexibility and interconnections that are increasingly powerful. From the analysis of Prof. Gruosso (Professor of the electronic information and bioengineering department of the Politecnico di Milano) is that the market is in constant movement and growth, economic and technological. The sector analyzed refers to the producers of assembly systems associated with AIDAM, the sample counts 34 Companies (28 Small and 6 Medium). The total turnover of small businesses is equivalent to the total turnover of medium-sized companies, with the same trend line to show that the sector reacted very similarly to the economic events that marked the previous period.

The 4th Industrial Revolution is here

On March 22, 2018 the conference entitled "From Industry 4.0 to Enterprise 4.0: digitization, security and skills" took place at the UCIMU headquarters in Cinisello Balsamo, Milan. The conference was aimed at exposing all aspects of the implemi-mation of digital technologies, from digitalization to cybersecurity in the digital factory. The numerous guests who took turns during the day reiterated the importance of investing in hardware and software material that increases the industrial companies value. Predictive training is essential to prepare the personnel who will be interfacing with the machines complying with the Enterprise 4.0 plan to ensure a high added value to production and to develop their technological skills in the digital factories that will be increasingly smart and 4.0.

From INDUSTRY 4.0 to BUSINESS 4.0

After the National Industry 4.0 Plan, which provided an incredible boost to the development of SMEs, now it is time for the Business Plan 4.0. The facilities available to companies are numerous: tax credit in research and development, customized training plans according to the reference sectors, Hyper and Super amortization and Sabatini Ter. These measures are made to ensure an improvement in production processes and digitize them as completely as possible. The careful planning of investments, the strong technological drive and the incentives are a fundamental opportunity for the qualitative renewal of companies in the national and international market.

Business Plan 4.0 - Innovation and skills

The Italian Minister Carlo Calenda presented the brilliant results of the nation plan INDUSTRIA 4.0, this plan was started in 2017. Subsequently, have been introduced he new actions for the new National Plan IMPRESA 4.0. Opened the proceedings, moderated by Andrea Cabrini (CNBC Class), the Minister of Economy and Finance, Pier Carlo Padoan. The President of the Council of Ministers, Paolo Gentiloni, closed the meeting. The presentation took place at the Officine Grandi Riparazioni (OGR), the new hub dedicated to creativity, innovation and business acceleration. LINK

UNIQUE MACHINES 4.0 READY

Primon Automazioni is an italian company leader in the construction of innovative and customized systems for handling, assembly and testing, properly designed to optimize the production cycle and increase the efficiency, competitiveness and profitability of the customer. Despite these features of uniqueness, the equipments supplied are all in line with the technical and functional requirements requested by the national plan INDUSTRIA 4.0, to ensure both the perfect integration with the management and production system in which they are used and the access to particular tax relief. To support entrepreneurs and production technicians in the choices of machines and technologies in line with the fourth industrial revolution Primon Automazioni has realized a guide brochure, in which they highlight the characteristics that their machines already have and any activities requested to the user for the insertion of the new equipment in the company.

High school students visit Primon Automazioni

For one day their classroom became the factory. A special lesson for the aspiring electronic experts of the "Cobianchi" Institute of Intra.A class left the banks of Piazza Martiri di Trarego to move one day to the Primon Automazioni of Verbania. In the plant, the students visited both the design offices and the production department, looking closely at what daily employees of Primon do to supply their customers, in Italy and in the world.

ISH 2019

ISH is the world’s leading trade fair focusing on the responsible management of water and energy in buildings. It sets trends for modern bathroom design, sustainable heating and air-conditioning technology as well as intelligent home systems. Frankfurt-Germany

Fiera Francoforte 2015

Fiera leader mondiale per Il Mondo del Bagno, Tecnica degli Edifici, delle Energie Rinnovabili, dell’Energia e della Climatizzazione.Francoforte – Germania